The inner workings of a truck’s engine contain several parts essential to its effective and efficient operation. The timing belt and timing chain are two of these items that are crucial for coordinating the internal engine parts’ motions. Timing chains and belts have the same general function; however, timing belts and chains have different builds, lifespans, and maintenance requirements. This article will examine the main distinctions between truck timing chains and belts.

What is a Timing Chain in a Commercial Truck?

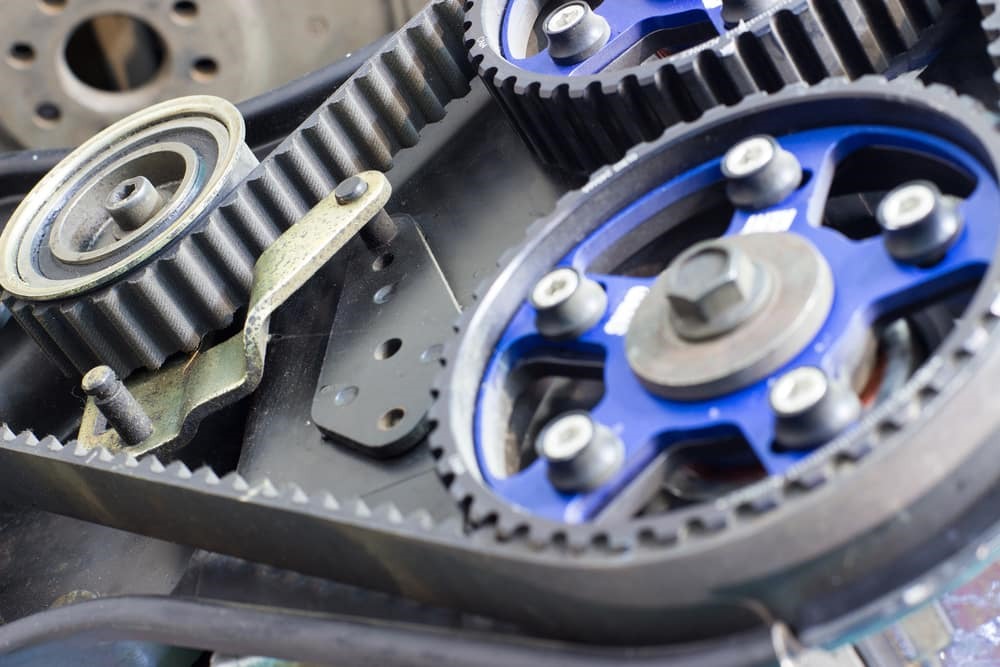

A timing chain is an internal engine component fitted to synchronize the camshaft and crankshaft rotation — these two elements are essential for driving the wheels. The chain’s movement allows engine cylinders to produce power to operate and propel the vehicle. The timing chain synchronizes the opening and closing of the engine valves, known as intake and exhaust valves. It allows them to move at the required intervals for the appropriate amount of fuel to enter the engine and for exhaust to exit the engine. The process produces the exact amount of internal combustion required to drive at the desired speed.

The timing chain is an absolutely essential truck part. Any vehicle that requires a timing chain will not operate without one. Since the timing chain is housed inside the engine, it receives its lubrication from the engine oil, which is essential for its smooth functions. Despite having a metallic composition, timing chains can wear off, get loose, or break due to stress.

Where is the Timing Chain of the Commercial Truck Located?

In most situations, the timing chain is attached to the front of the engine (the right side in front-wheel drive trucks), though this is not always true. It is covered in plastic, which must be taken off to access the chain.

How Much is a Timing Chain?

A professional can change timing chains for $1,600 to $1,800, or you can do it for $600 to $800. The cost is significant because it’s challenging to replace this component. It will cost roughly $650 in parts to replace a timing chain yourself. But someone who has extensive experience working on commercial & Semi Truck Repair Shop should perform this task. The parts for the majority of autos may be purchased for under $20. On the other hand, the cost of labour may be significantly higher.

This pricing range excludes taxes, fees, and the particular make and model of your vehicle and is based on national averages for all vehicles. Other repairs or maintenance may need to be done, such as replacing the valve cover gasket.

In this case, the brand and model of the truck are very important. One engine might have a timing chain that is easy to get to. It could also have a small number of tension gauges and pulleys. So, it might be possible to change the timing chain in just a few hours. In other cases, the system is much more complicated, and the mechanic might have to lift the engine out of the truck to remove the timing chain.

What Does a Timing Chain do in a Semi-Truck?

An engine’s timing chain keeps the movement of the components in the top half of an engine synchronized with those in the bottom half. In the top part of the engine, the timing chain is attached to the end of the camshaft, which has numerous lobes along its length. As the camshaft spins, these lobes open and close the valves in the cylinder head to let fuel and air into the combustion chamber at the right time. The valves also allow exhaust gases to exit once the fuel and air have been compressed and ignited.

The crankshaft, which rotates and raises and lowers the pistons at precisely the right times to compress the fuel and air before ignition, is also connected to the timing chain at the bottom of the engine. Because they were lighter and more effective, timing chains primarily supplanted gear-driven timing systems. However, during the 1970s and 1980s, toothed timing belts largely replaced them because they didn’t require lubrication like timing chains. However, due to its increased durability and longer life expectancy, the timing chain has returned to being widely used throughout the previous few decades.

Timing chains also tend to give much more warning before they fail. They stretch slightly over the time, which can cause the engine to run poorly or even backfire, which is a good sign to get the chain replaced imminently. A worn timing chain will also emit a rattling noise. Timing belts tend to snap, which can cause huge internal engine damage in an instant, as valves open at the wrong moment and hit the top of the rising piston. Such damage can often write off an engine completely, hence the increasing popularity of the timing chain once more.

How Do I Know if the Timing Chain of the Truck Needs Replacing?

A worn timing chain exhibits some symptoms that signify that the timing chain is not functioning properly. These signs include:

A Rattling Sound on Starting the Engine of Idling

A common finding in a vehicle with a bad timing chain is the unusual rattling noise when the engine is started or when brakes are engaged. It happens due to the loose or stretched timing chain that shakes and rattles while rotating when the engine motor is running.

Misfiring Engine

Since the timing chain times the opening and closing of engine valves, any damage can unbalance the air-fuel ratio and result in a lack of power. It appears as a jerking motion and loss of acceleration.

Contaminated Engine Oil

Another warning sign is finding metal bits in the engine oil. Metal parts from a damaged timing chain may break off and land in the oil. This finding must prompt the owner or mechanic to inspect the timing chain.

Check Engine Light

Just like any other misfunctioning component of the engine, a faulty timing chain will illuminate the check engine light. It is a warning to get your vehicle assessed for underlying engine problems, which might include a bad timing chain.

Inability to Start the Engine

This is a sign of the ultimate breakage of the timing chain. The vehicle won’t start and can also damage other engine components.

If these signs are recognized timely, the impending failure of the timing chain can be prevented with proper repair services. If you suspect that your vehicle’s timing chain needs repair, call our auto repair shop today!

Broken Plastic Timing Guide and Metal Shaving

If your timing chain is worn out, little metal pieces may come loose and land in the oil pan. When you get your oil changed, if your mechanic finds tiny metal fragments in the oil as it is being drained or in the filter, it may indicate that your timing chain is beginning to fail. However, a number of additional problems could lead to metal shavings in the oil. Contact your manufacturer or service provider as soon as you notice metal in your oil for an inspection, accurate diagnosis, and suitable repair.

Lack of Power

Because the valves are not opening and shutting at the proper times, a timing chain that has stretched sufficiently to skip some teeth on the sprocket will not allow the combustion chambers to pull in the necessary quantity of fuel and air mixture. This results in a considerable loss of power and reduces the engine’s responsiveness to accelerator pedal input.

Timing Related Codes

The variable valve timing system enhances engine performance and fuel efficiency by managing the opening and closing of the intake and exhaust valves. Oil control valves, sometimes referred to as solenoid valves and VVT (variable valve timing control) valves, are used by the ECM to regulate the camshaft(s).

Timing-related faults significantly impact your truckr’s ability to be driven. The most frequent problems are an increase in engine stalling, a rough idle, poor fuel economy, and rattling or knocking noises coming from the engine. The internal engine components may suffer substantial harm if the truck is driven further in this state.

How Much for a Timing Chain Replacement of a Truck?

Timing chain replacement typically costs between $1,000 and $2,500 (labour and parts combined). The precise sum depends on the make and model of your truck and your particular region.

Although some timing chain kits cost up to $500, the timing chain is only $100 to $250. A good timing chain kit includes gears, tensioners, and sometimes even the water pump. Costs of labour range from $400 to $1500. It takes a lot of time and effort to replace the timing chain because it requires disassembling many engine components. If the timing is set incorrectly, the engine could also sustain serious damage and require rebuilding or replacement.

Timing Belt vs Timing Chain Pros and Cons

Timing Belt Vs. Timing Chain

The timing belt vs timing chain are the mechanisms that connect the crankshaft. When you open your hood, you won’t be able to see them. Timing belts and chains are always concealed beneath timing covers made of plastic or metal. These maintain the camshaft timing stable regardless of the environment outside the engine.

The timing chain performs the same duties as a timing belt. The two are just different in terms of substance and location. One is made of metal, while the other is made of reinforced rubber.

Timing Belt

- Timing belts are perforated rubber belts with high tensile fibres.

- When compared to the timing chain, the timing belt manages less power.

- Compared to the timing chain, it has a shorter life.

- It is more affordable.

- No lubrication is required.

- It has the potential to slip.

Timing Chain

- Metal alloys are used to make the timing chain.

- It makes greater noise.

- Lubrication is necessary.

- Slippage is impossible.

- It costs more.

- It is more durable.

Advantages and Disadvantages of Timing Belt Vs. Timing Chain

Timing chains are often preferred over chains, especially in newer vehicles. This is due to the longevity of timing chains. Both, however, have advantages and disadvantages. Before you decide which is preferable, you need to understand the advantages and disadvantages of timing belt versus timing chain so you can make an informed conclusion.

Timing Belt Advantages

- There is very little vibration and chordal influence.

- Precise timing and registration with no loss of high torque carrying capacity.

- The timing belt has a good slip-resistant engagement.

- When properly serviced, belts have an efficiency close to 100%.

- There is little noise.

- Service that is long, dependable, and problem-free.

- Rust resistance.

- Weight is saved.

- Excellent resistance to wear.

- It conserves energy.

Timing Belt Disadvantages

- You should change your belt on a regular basis.

- Some engines rely on the water pump.

- Drivers must pay close attention.

Advantages of Timing Chain

- You do not need to replace your water pump while repairing a bad timing belt.

- Timing chains are quite robust.

- It does not expand.

- There is no slippage.

Disadvantages of Timing Chain

- Expensive to buy.

- Lubrication is required.

- Hydraulic pressure is required for chains to function.

What is a Timing Belt in a Commercial truck?

Thanks to the timing belt, your engine’s valves and pistons will all work together in perfect harmony. By controlling the crankshaft and camshaft revolutions, it does this. Timing belts frequently fail between 60,000 and 100,000 miles.. You can find more specific replacement intervals in your owner’s manual by B&S truck Commercial & Semi Truck Repair Shop.

More than just the belt itself is included in a timing belt service. Although everyone has a tendency to view this shift as “just the belt,” it is not. A set of tensioners and idler pulleys, each with bearings and susceptible to failure, tension and hold a timing belt in place. The timing belt also powers the water pump used in many automobiles. Since the work to expose the pump is already being done in these situations, replacing it with a new unit at the same time makes perfect sense.

How Much is a Timing Belt in a Semi Truck?

There is nothing worse than paying for a timing belt service, declining the water pump replacement for an additional $100, only to find out 6 months later that the water pump is leaking, and now everything must be replaced again.

A timing belt kit usually consists of the belt itself, 2-3 idler pulleys, and a tensioner. When the job is done, all these components will be changed. A timing belt kit will usually run between $100 -350.

Labor on most timing belts is between 3-5 hours, putting your total cost between $400 -1,000. Remember, do not opt for a “just the belt” replacement. While the cost is cheaper, the chances of further failure increase significantly. If the water pump is being done at the same time, the labour should be minimal, and less than 1 hour, as the work to expose the water pump and remove the timing belt is being done anyway. Working in with best truck repair and cheap muffler shops near me is always a privilege for you. like B&S truck don’t charge extra from the customers.

What Does a Timing Belt Do?

The timing belt is an essential component of the engine in your truck. It keeps many of the moving elements precisely timed to create maximum efficiency and power. It’s crucial to keep up with any necessary maintenance in that region and have the belt replaced in accordance with the service period specified in your vehicle’s owner’s handbook because a broken timing belt can result in catastrophic engine failure.

Your timing belt synchronizes the engine’s combustion cycle by linking the crankshaft and camshaft. The intake and exhaust valves are moved by the camshaft, which also rotates in conjunction with the pistons.

What Causes the Timing Belt to Break in the Truck?

With the help of B&S Truck Repair, Commercial & Semi Truck Repair Shop. We’ve put together a list of problems and possible causes to help you identify the reason for timing belt failure. Visually examine your timing belt drives for these top 6 failure-causing problems, and it could help to prevent your drives from grinding to a halt, avoiding unscheduled downtime.

1. Misalignment

Misalignment is one of the main causes of timing belt drive failure. Excessive or uneven tooth wear, belt tracking and tensile failure can all be attributed to misalignment. By checking and aligning your shafts and timing pulleys, you can increase your timing belts’ life and save you lots of downtime.

2. Excessive load

If the timing belt teeth are shearing, excessive load is more than likely the cause. Extreme or shock loads can also cause tensile failure and excessive tooth wear, although the latter is less likely. To cure this problem, you’re going to have to redesign the drive.

3. Under-tensioned Belt

Tooth skipping, also called ‘ratcheting’, is probably down to your belt being under-tensioned. Under-tensioning can also cause excessive or uneven tooth wear and excessive drive noise, so use a tension gauge to set the correct tension on those timing belts!

4. Weak drive structure

If your drive vibrates excessively or your timing belts suffer from apparent belt stretch, you could have a weak drive structure. Try reinforcing the driving structure, and you could stop the problem.

5. Damaged or worn pulleys

Damaged or worn timing pulleys will substantially reduce belt life. Worn teeth will cause belt wear and/or damage. Nicks or gouges can cut the belt. Inspect and replace pulleys that show signs of wear.

6 Debris in the timing pulley or drive

It’s the most overlooked, but debris can cause a multitude of problems for your timing belt & pulley. Dirt on the teeth can abrade the belt, and oil can attack the belt materials. Use a stiff brush to clean off rust and dirt. Wipe clean of oil and grease. Debris can account for any of the above reasons for timing belt failure, so clean those pulleys and fit a shield to that drive!

How Long can you Drive with a Bad Timing Belt?

A loosened timing belt is the last thing you want to think about while driving. You can have an extremely difficult time if your timing belt breaks.

A common question is how long we can drive with a broken or malfunctioning timing belt. The straightforward reply is not even a second. Yes, you should have taken care of your timing belt a year earlier if you’ve already discovered it may cause problems.

A broken timing belt prevents you from travelling more than one mile. You shouldn’t, even if you can, because you wouldn’t want your engine to break down in the middle of the road.

How Much is a Timing Belt Replacement?

Depending on your vehicle, a timing belt service could become a big deal, and it will be costly. Having a timing belt replaced before it breaks will cost between $500 and $1,000 on average, while waiting for it to break before replacing can cost upward of $2,000 or more, especially if other damage occurred. But commercial & Semi Truck Repair Shop can give you your required work done in reasonable amount.

What Happens when Timing Belt Breaks in a Truck?

First, the camshaft stops moving, and all timing is lost. Then, the pistons crash into the valves, damaging both parts. Depending on how hard the pistons and valves collide, you might also end up with decimated cylinder walls. The broken timing belt takes out this entire portion of the engine.

It’s important to replace your timing belt at the mileage intervals your vehicle manufacturer recommends. Every manufacturer is different, but typically, it needs to be replaced every 60,000–100,000 miles. Your vehicle’s vehicle’s recommended interval can be found in your truck’s owner’s manual.

Because the timing belt is made of rubber, it will wear down over time and eventually break. When it breaks, the engine will stop running, or the components will be out of sync, damaging the engine.

If you don’t replace the timing belt at the recommended time, you could end up with total engine failure, broken or bent valves, cylinder head or camshaft damage, and piston and cylinder wall damage. This is not the type of situation where it’s safe to think: ‘If it’s not broken, don’t fix it.’ Replace the timing belt according to the manufacturer’s maintenance schedule to avoid thousands of dollars repairing or replacing your engine.

When to Change Timing Belt of Truck

The specific timing belt replacement interval for a truck can vary depending on the make and model of the truck, as well as the engine it has. As a general guideline, most trucks, like cars, have timing belt replacement intervals that fall in the range of 60,000 to 100,000 miles, or every 5 to 7 years, whichever comes first.

Bottom line

In conclusion, your truck’s timing chain or belt should be chosen based on your budget, maintenance preferences, and your truck’s application. Timing chains are preferred for their sturdiness and long-term dependability, whilst timing belts offer quieter operation and reduced initial replacement costs. You may make an informed choice about this important truck engine part by carefully weighing your unique requirements and the manufacturer’s suggestions.